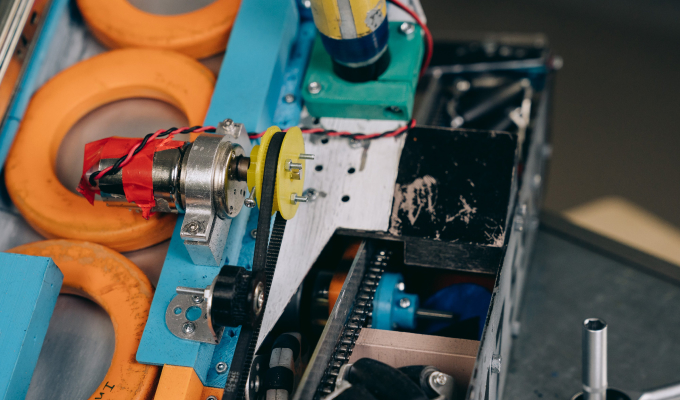

Manufacturing defects refer to faults or imperfections in products or components that do not meet specified quality standards. They are a concern because they can lead to reduced product quality, increased production costs, and decreased customer satisfaction.

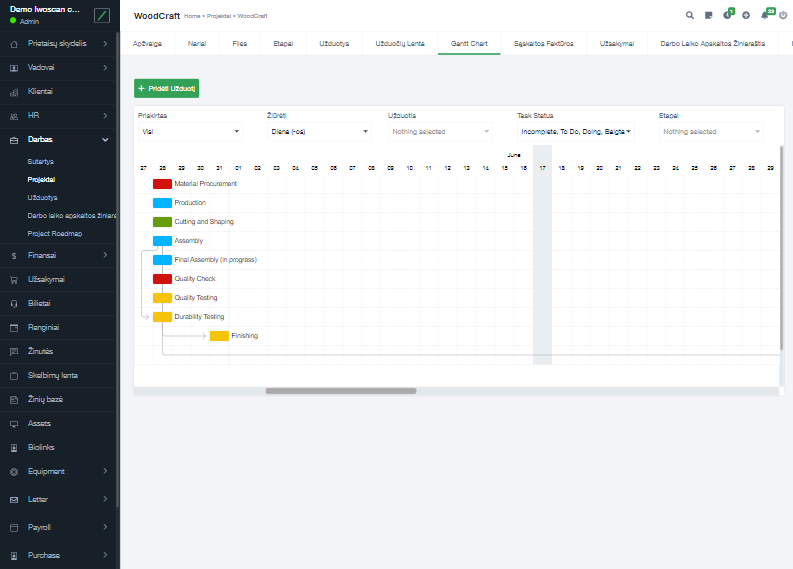

Iwoscan is a versatile tool designed to monitor various aspects of production processes. It can track and analyse manufacturing defects in real time, providing insights into when and where defects occur. This data helps businesses identify and address the root causes of defects, leading to improved product quality.

Iwoscan can be customised to detect and track defects, including dimensional inaccuracies, material flaws, assembly errors, and more. It can capture defect frequency, location, and severity data, allowing for targeted quality improvements.

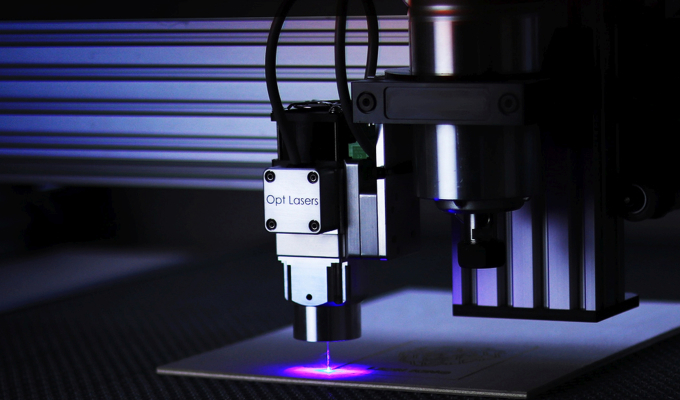

Iwoscan helps reduce the need for costly rework, scrap, and warranty claims by promptly identifying and addressing manufacturing defects. This leads to cost savings and increased operational efficiency.

Yes, Iwoscan is designed for seamless integration into various manufacturing setups. It can be adapted to work alongside existing quality control measures and equipment, ensuring minimal disruption to production workflows.

Yes, Iwoscan's flexibility suits businesses of all sizes, from small-scale operations to extensive manufacturing facilities. It can be tailored to meet different organisations' needs and budget constraints.

Iwoscan is user-friendly and comes with comprehensive training and support. While some training may be necessary to maximise its potential, it is designed to be accessible to manufacturing teams with varying levels of technical expertise.

Businesses can expect improved product quality, reduced production costs, enhanced customer satisfaction, and greater operational efficiency. Iwoscan helps companies to achieve a defect-free manufacturing environment.

Yes, Iwoscan can complement existing quality control tools and methodologies. Its data can be integrated into broader quality management systems for a comprehensive defect monitoring and prevention approach.

The timeline for results can vary depending on the specific manufacturing processes and the extent of defects. However, many businesses report noticeable improvements in product quality and defect reduction shortly after implementing Iwoscan.

Let's dive right into how Iwoscan can reshape your manufacturing pipeline

Let's dive right into how Iwoscan can reshape your manufacturing pipeline