Error-Prone Assembly

Manual assembly is susceptible to errors, impacting product quality and efficiency. Eliminating errors is essential for efficient assembly operations.

Embark on a new era of manual assembly excellence with Iwoscan. Discover how our cutting-edge features redefine precision, eliminate errors, and boost efficiency in every assembly process.

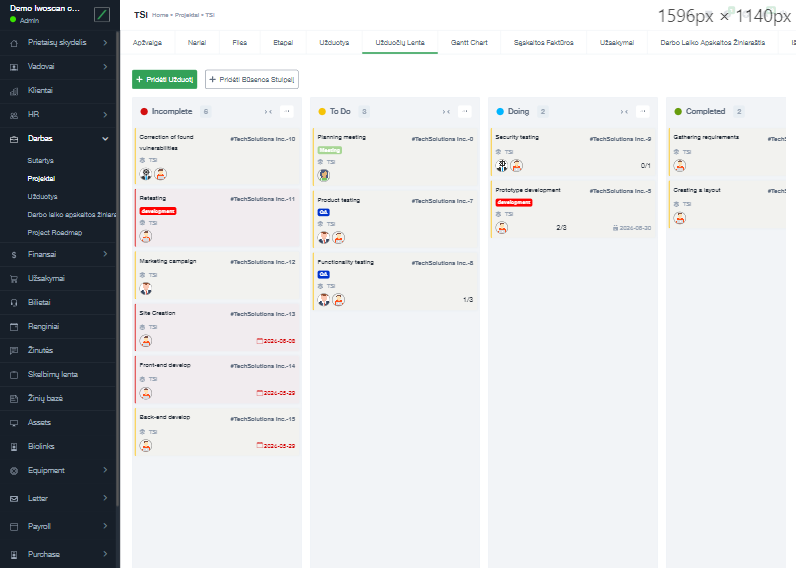

Odoo ERP friendly

Odoo ERP friendly Built-in task splitting and merging

Built-in task splitting and merging Raw data without distortion

Raw data without distortion

Dive deep into how Iwoscan, your unwavering Manual Assembly Optimization Partner, takes on pivotal challenges, erases errors, and nurtures a culture of operational excellence.

Our feature set is engineered to empower your business with precision, security, and comprehensive insights, ensuring you stay at the forefront of innovation in your industry.

Enhance your operations through real-time process monitoring, effective anomaly tracking, and instant insights within a user-friendly interface to optimise processes.

Optimise your operations by implementing employee productivity monitoring, production anomalies tracking, and enhancing quality control efficiency.

Get instant access to critical data and analytics, enabling swift decision-making and precise performance evaluation, all within the Iwoscan platform.

Iwoscan provides robust data security, ensuring your information remains safe and accessible on the device for up to two years, giving you peace of mind and long-term data retention capabilities.

Facilitate effortless communication with your workforce, harness performance recognition and reward functionalities, and establish ongoing feedback loops for continuous improvement.

An intuitive interface ensures effortless process optimisation, complemented by a crystal-clear LED display for enhanced visibility.

Choose from various flexible data export formats, including CSV, JSON, HTML table, and binary. Additionally, you can generate reports directly in your web browser or download raw data in .csv format.

Maximise your efficiency with the integrated text input for event logging, precise timing using clock functionality, and versatile data capture with built-in barcode reading and RFID capabilities, ensuring seamless operations and comprehensive tracking of events.

Achieve smooth Wi-Fi communication, simplified device setup, and operation, while interactive dashboards provide precise insights for enhancing operational efficiency, making the most of your connected experience.

Our system operates independently, ensuring no reliance on external servers for basic data processing, guaranteeing your data's security and availability.

Enter the world of manual assembly, where precision reigns supreme, yet challenges loom large. Discover how Iwoscan, your dedicated Manual Assembly Optimization Partner, embarks on a relentless journey to address critical issues, obliterate errors, and nurture a culture of assembly excellence.

Manual assembly is susceptible to errors, impacting product quality and efficiency. Eliminating errors is essential for efficient assembly operations.

Efficient utilization of assembly time is critical for meeting production demands. Precise tracking and analysis of assembly processes are necessary for optimization.

Maintaining product quality is vital. Detecting and rectifying quality issues promptly is crucial for error-free manual assembly.

Effective training is necessary for skilled assembly workers. Identifying skill development needs is key to a proficient assembly team.

Managing inventory efficiently reduces delays. Optimizing inventory levels is essential for streamlined manual assembly operations.

Imagine a reality where efficiency is second nature, productivity soars, and bottlenecks vanish. We're about to unveil solutions that will make your workplace a hub of unparalleled excellence.

Let's make your vision a reality!

Iwoscan significantly enhances manual assembly efficiency by detecting errors in real-time, optimising assembly time, ensuring quality control, and facilitating workforce training. It ultimately leads to error-free assembly processes and increased productivity.

Iwoscan employs real-time tracking and analysis to identify errors as they occur, offering instant feedback to assembly teams. Pinpointing the source of errors helps organisations implement corrective measures and ensure error-free assembly.

Absolutely. Iwoscan provides precise tracking and analysis of assembly processes, allowing organisations to identify bottlenecks and inefficiencies. This data enables better utilisation of assembly time, ensuring products are assembled promptly and efficiently.

Iwoscan continually monitors assembly processes, instantly detecting quality issues. It allows immediate intervention and correction, ensuring that products meet quality standards throughout the assembly process.

Yes, Iwoscan offers a user-friendly interface and seamlessly integrates with various assembly processes, making it adaptable to various industries, from electronics to automotive.

Certainly, Iwoscan identifies skill development needs within your assembly team, enabling organisations to tailor training programs and enhance the proficiency of assembly workers.

Iwoscan's real-time monitoring helps organisations manage inventory more efficiently, reducing delays and ensuring a streamlined assembly process. It optimises inventory levels for seamless manual assembly operations.

Yes, Iwoscan's scalability makes it suitable for businesses of all sizes. Whether you have a large-scale manufacturing facility or a small assembly operation, Iwoscan can be tailored to meet your needs.

No, Iwoscan does not rely on external servers for basic data processing. It stores data securely on the device for up to two years, ensuring operational continuity without extensive server infrastructure.

Iwoscan offers a simplified setup and operation process. Our support team can assist you in implementing Iwoscan seamlessly into your manual assembly workflow to start reaping the benefits of improved efficiency and accuracy.