Iwoweight is a hardware solution for manual packaging and quality control procedures.

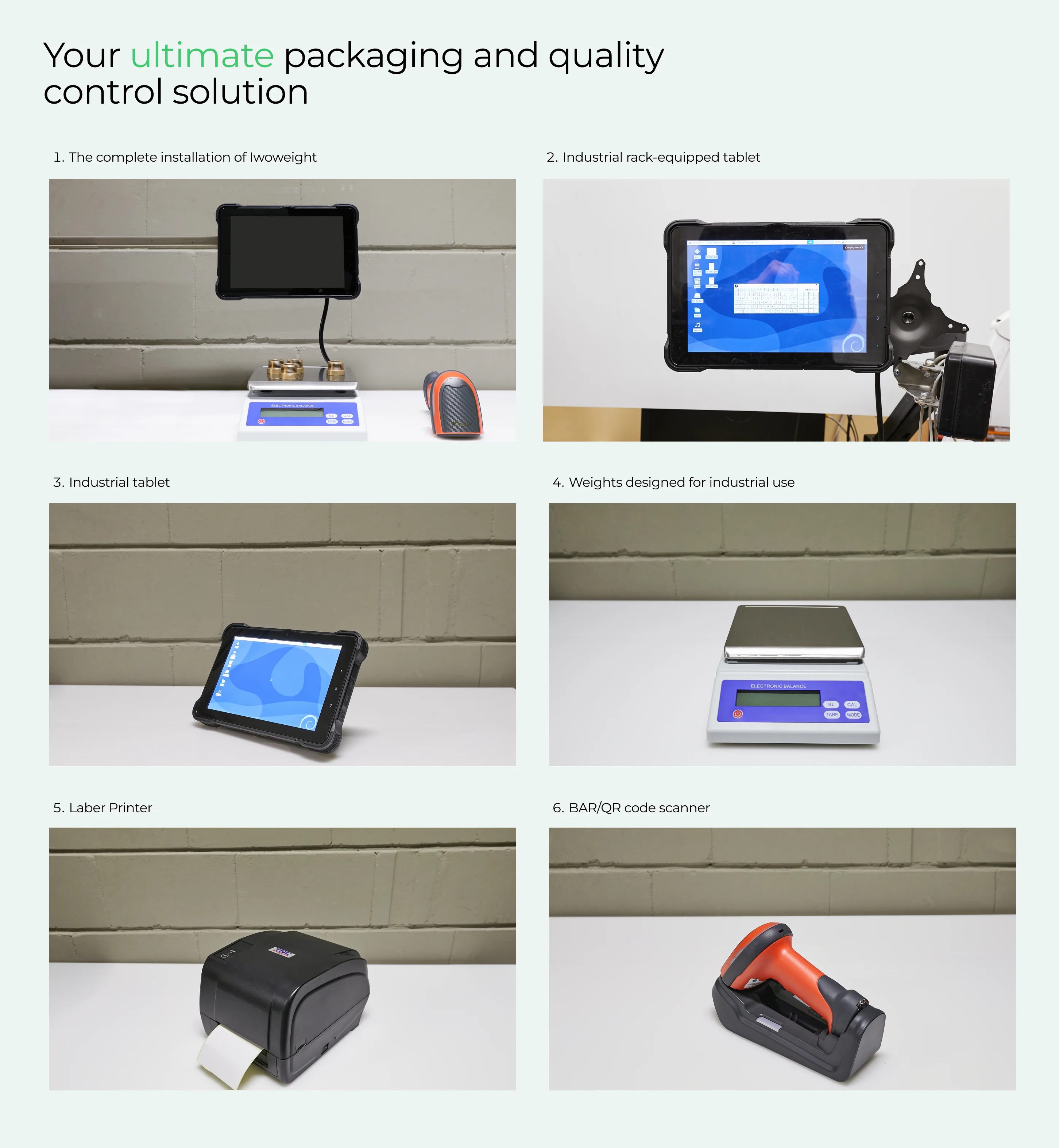

How does it look?

The Iwoweight solution comprises various components of both hardware and software:

- Industrial Counter

- Weighing scales with a weight range in any category

- Holder for iwoweight device

- Label Printer

- Build-in BAR/QR code reader

- Remote scanner

Why do you need Iwoweight?

Perhaps you are tired of packaging errors and quality control mishaps? Are you searching for methods to enhance precision, boost efficiency, and closely oversee production and packaging procedures? Look no further. Iwoweight is the exclusive solution to elevating your performance and maximising your return on investment. Additionally, it serves as an ideal tool for employee time tracking.

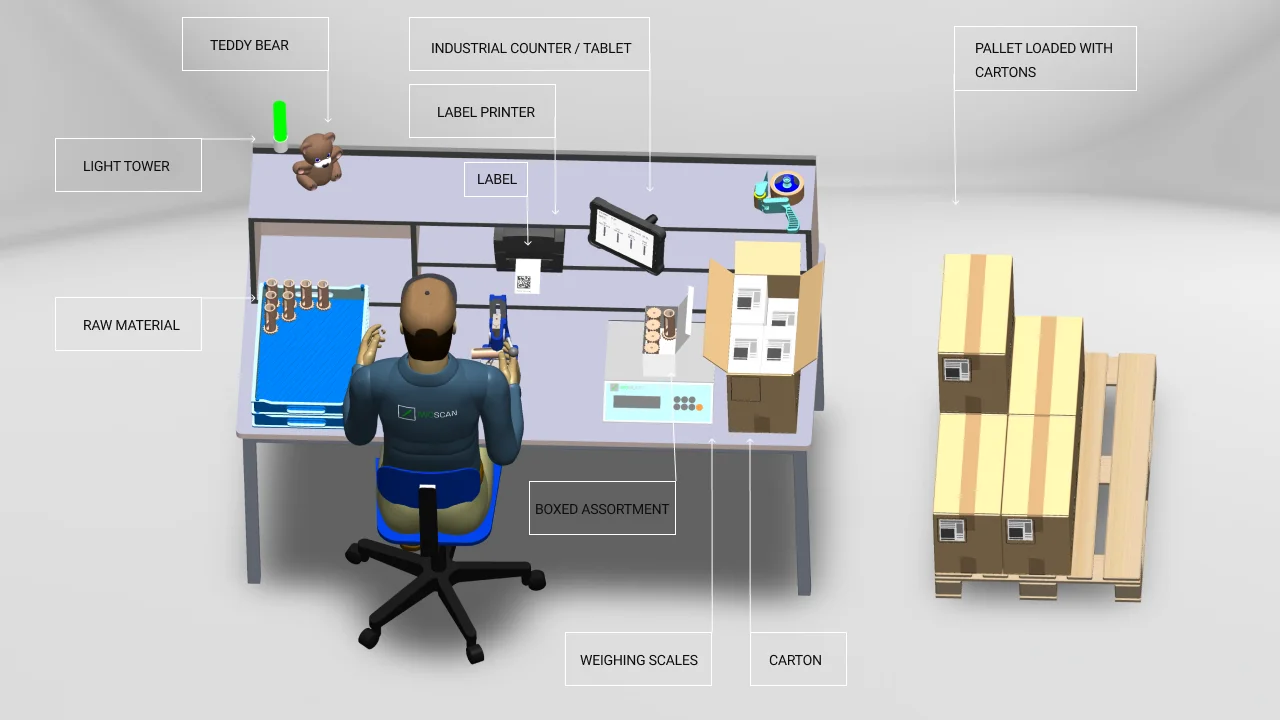

Example of Iwoweight in action

Here's an actual scenario to provide a clearer understanding of how Iwoweight is relevant in specific workplace settings. In the depicted scene, an operator is seated in a workspace equipped with the Iwoweight solution. This system seamlessly integrates with scales, continually overseeing package weights to guarantee accuracy and promptly detect deviations.

The operator receives incoming raw materials

Upon receiving raw materials for crafting specific parts, the operator logs into the system by scanning its barcode and promptly accesses task instructions and batch details on the tablet screen. This eradicates the need for prolonged contemplation or uncertainty about the next steps, as Iwoweight seamlessly guides the process.

The production process in progress

Linked to scales, Iwoweight conscientiously observes and records the weight of every item assembled by the operator. There's no longer a need to question the possibility of errors or whether the package aligns with the designated weight.

An Iwoweight can oversee the weighing process for a wide array of items in almost any production line. These items may vary in weight, ranging from less than a gram to several hundred kilograms.

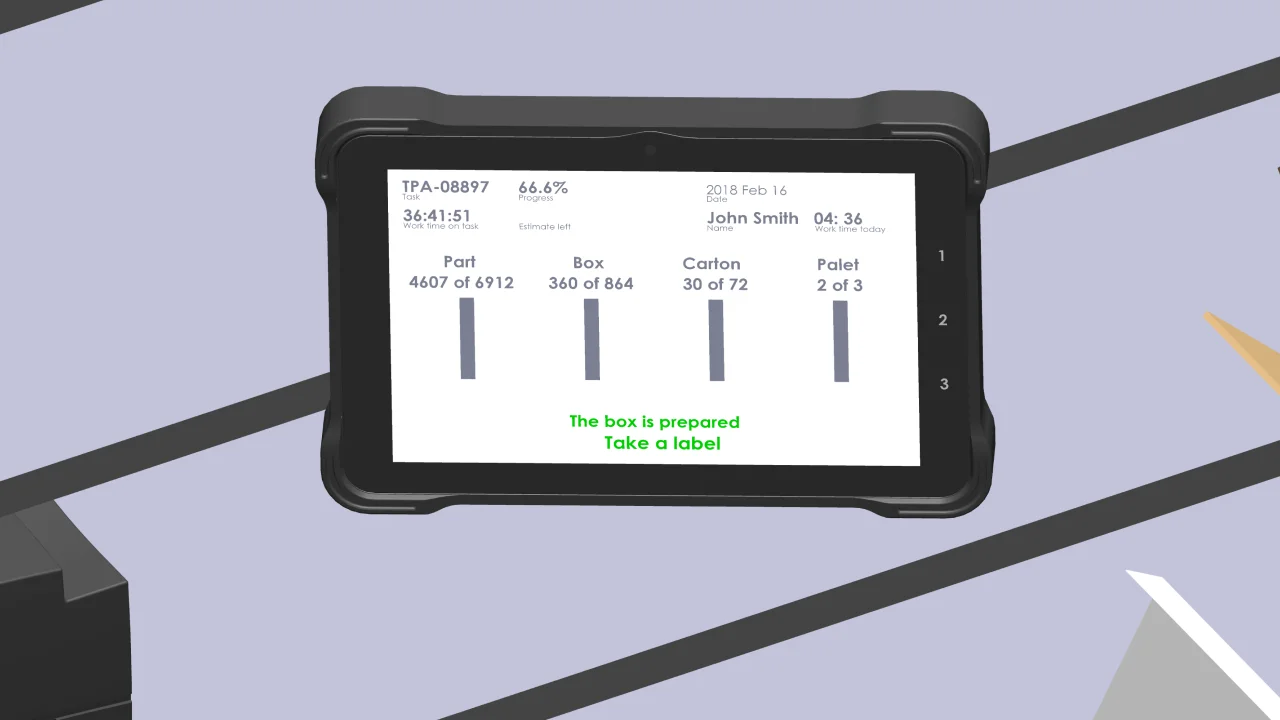

Illustration of a three-tier packaging process: box, carton, pallet.

There is a significant risk of making errors during the three-tier packing process. However, with Iwoweight, everyone involved in the operation remains well-informed about the quantities and weights of products, minimising the likelihood of mistakes.

The importance of label printing

Bid farewell to packaging errors. Once the packaging is done, Iwoweight will print a customised sticker (logo, weight, date, operator name, and more) for you. It's cost-efficient and saves valuable workforce. With the ability to print (self-designed, customised (free templates) stickers and track real-time work hours, Iwoweight is your solution for error-free packaging, cost efficiency, and precise task management, providing invaluable insights into your business processes.

Final stage

Once the job is completed and all boxes are placed in cartons stacked on pallets, the system concludes the task and seamlessly transitions to the next one.

However, there's more to Iwoweight! Besides packaging, Iwoweight is a crucial instrument for tracking your team's real-time working hours. Bid farewell to cumbersome check-in and check-out systems; opt for precise task management and meticulous tracking of working hours. Additionally, it allows for data collection internally, retaining at least a two-year history, and offers data export options in CSV, HTML, or JSON formats.

Let’s talk Iwoweight!

Iwoweight's adaptability extends across diverse industries, rendering it an essential tool. Regardless of your sector, Iwoweight is key to achieving precision, cost-effectiveness, and quality assurance in your packaging and quality control procedures. Engage to discover the benefits of implementing Iwoweight in your company.

Let's dive right into how Iwoscan can reshape your manufacturing pipeline

Let's dive right into how Iwoscan can reshape your manufacturing pipeline

Comments

No comments yet!Add a Comment

You must be logged in to post a comment.