In manufacturing, where precision and efficiency are paramount, Iwoscan emerges as the quintessential solution for optimising your production lines. Regardless of your industry—manufacturing, bakery, furniture, or auto service—Iwoscan is the catalyst for transformative results.

Experience a seamless integration that goes beyond conventional solutions. Iwoscan offers real-time guidance as a strategic tool to steer your production processes towards unparalleled precision. Our system protects against potential setbacks by preventing costly errors ensuring a streamlined workflow. Language barriers are effortlessly bridged with Iwoscan, promoting clear communication and collaboration across diverse teams. Boosting team motivation is an inherent benefit, as the system empowers operators with the tools they need for optimal performance, fostering a motivated and engaged workforce. What sets Iwoscan apart is its unique traceability feature—an invaluable asset in gaining actionable insights into your production processes. Uncover trends, identify areas for improvement, and make informed decisions that elevate overall efficiency. Iwoscan isn't just another solution; it's the indispensable companion your production line deserves. Envision an ultra-smart hardware ally seamlessly integrated into your operations, guiding operators in real-time. This translates to enhanced precision, reduced errors, and an overall boost in efficiency. For decision-makers in the manufacturing industry, Iwoscan is the gateway to a future where every aspect of your production line is optimised for success. At the heart of industrial evolution, Iwoscan is the pivotal solution for decision-makers in the manufacturing industry seeking heightened efficiency within their production lines. This innovative hardware seamlessly integrates with any industrial machine, serving as the linchpin for transformative advancements. Functioning as a robust data collection tool, Iwoscan goes beyond mere integration; it becomes an indispensable asset for operators facilitating task optimisation and providing insights into downtime identification. The gathered data primarily aids in task planning and performance monitoring, with limited relevance for the operator in historical contexts. Its adaptability knows no bounds, positioning it as the optimal answer to many challenges in the manufacturing sector. The Iwoscan hardware device offers two distinct types, each tailored to deliver comprehensive benefits. For factories equipped with tablets or PCs at their workstations, the basic Iwoscan setup is the ideal choice. Opting for the Basic set grants access to essential features and unlocks PRO functionality, utilising your PC as the intuitive user interface. Iwoscan isn't just a hardware solution; it's a strategic investment for decision-makers aiming to improve their manufacturing processes. By seamlessly integrating with existing machinery, providing valuable insights, and offering versatile functionality, Iwoscan becomes an indispensable tool for enhanced efficiency on the production line. The foundational Iwoscan industrial counter comes equipped with a mounting rack exhibiting a straightforward design. Are you looking to elevate your production lines? The Basic Set is your go-to choice, especially if your workstations boast tablets or PCs. It's also the perfect fit if a user interface is optional in your workplace. But that's not all – this option comes packed with additional benefits. Each Iwoscan Basic Set delivers a range of values (remember, one set links up with just one workspace), providing you with: Iwoscan isn't just a solution; it's a dynamic experience designed to empower and elevate your operations. Too good to be true? Take a peek at the captivating pricing details of our solutions and subscription plans! Brace yourself for valuable discounts when you opt for quantity buying (Make a solid investment with reasonable value. If you purchase more than 10 sets, you will get a cost-efficient bargain) and subscribe for the long haul (enjoy a 10%, 15% or 20% discount on annual subscriptions, depending on the plan). And here's the cherry on top: a 60-day money-back guarantee to ensure your satisfaction! Your journey with us just got a whole lot more exciting. Upgrade your manufacturing processes with the Iwoscan Premium Set! Unleash a wave of unparalleled efficiency, heightened productivity, and insightful operations that will reshape the future of your manufacturing endeavours. We're committed to propelling you forward, introducing innovation into your operations with every step. But that's not all—the Premium Set exceeds expectations, delivering more advanced technology and additional benefits. This time, our solution comes with an industrial counter, a sturdy mounting rack, and a cutting-edge rugged tablet. Elevate your manufacturing game and embrace a seamless future where efficiency and innovation merge. Image: Iwoscan premium tablet 0 1.webp Meet Iwoscan, your state-of-the-art intelligent workplace companion, bringing a spectrum of benefits (remember, one set connects with just one workspace but is available for multiple employees). Our advanced hardware solution optimises lean methodologies, eradicating bottlenecks across manufacturing pipelines and seamlessly orchestrating task division. Discover the discounts based on the quantity of your purchase. Check out the pricing of our solutions and subscription plans. If you think efficiency comes with a hefty price tag, think again! Iwoscan presents budget-friendly technology solutions for small manufacturing businesses with just a handful of employees and large-scale manufacturing companies. With various subscription plans designed to enhance support throughout the process, Iwoscan ensures that cost is never a barrier to advancement. Our pricing is business-friendly, and we highly recommend the pinnacle of support plans for all types of companies – the Enterprise subscription. For just €34 per workplace, you unlock 360-degree assistance featuring:

Privacy-Boosted Data Your settings find a secure home in a cloud-based service. Cloud-Powered Data Backup (Optional but Potent) Automatically backup and restore your data on a cloud server for added security (essential for advanced functionality). Effortless Data Flow Efficiently transmit data to your ODOO 16 ERP/MRP server or any customised database. If your device has been on our basic plan for two years, effortlessly transfer historical data to our cloud service. Automated Task Processing Integrate with ODOO 16 or other MRP systems for automated task processing (additional charges may apply for specific custom requirements). Workspace Fusion Experience sophisticated data processing and reporting in the cloud. Enjoy consolidated data reports that seamlessly combine information from individual workspaces (where each workspace corresponds to one Iwoscan device). Unleash the Power of Iwoscan Maximise the capabilities of Iwoscan without stretching your budget. Your journey to advanced data management starts here.

Embrace the capabilities of Iwoscan without straining your budget. Your engineers can easily and quickly install Iwoscan hardware, connecting it to your manufacturing line. Our team is ready to assist and advise on integrating Iwoscan devices into each piece of machinery in your factory, orchestrating a shift from chaos to seamless efficiency. The duration of this transformative process, which can span from a few days to a couple of months, depends on your factory's size and the complexity of the data. This period marks the conclusion of our consultations or on-site intervention. It's pivotal to underscore that Iwoscan isn't just a technological fix; it's a catalyst for humans to achieve superior results. Remember, empowering your team to navigate and leverage Iwoscan is the key to elevating production efficiency. So, dive in, explore, and unleash the full potential of Iwoscan in your manufacturing journey! Immerse your business in a feature set meticulously crafted to infuse precision, security, and profound insights. Stay at the forefront, navigating emerging downtime and fluctuating overall equipment effectiveness. Your journey to excellence begins with our empowering features! Task handling Iwoscan's Task Handling feature efficiently manages and oversees various tasks within your manufacturing process, ensuring streamlined operations and enhanced productivity. Tracking employee performance This feature encompasses various functions, including employee work time accounting, performance monitoring, tools for employee salary calculations, and task preparation. It offers a comprehensive solution for tracking and managing labour hours, ensuring accuracy, and facilitating efficient workforce management. Live Process Analytics Enhance your operations through real-time process monitoring, effective anomaly tracking, and instant insights within a user-friendly interface to optimise processes. Streamlined Monitoring Optimise your operations by implementing employee productivity monitoring, production anomalies tracking, and enhancing quality control efficiency. Real-Time Insights Get instant access to critical data and analytics, enabling swift decision-making and precise performance evaluation, all within the Iwoscan platform. Flawless Interface An intuitive interface ensures effortless process optimisation, complemented by a crystal-clear LED display for enhanced visibility. Diverse Data Export Choose from various flexible data export formats, including CSV, JSON, HTML table, and binary. Additionally, you can generate reports directly in your web browser or download raw data in .csv format.

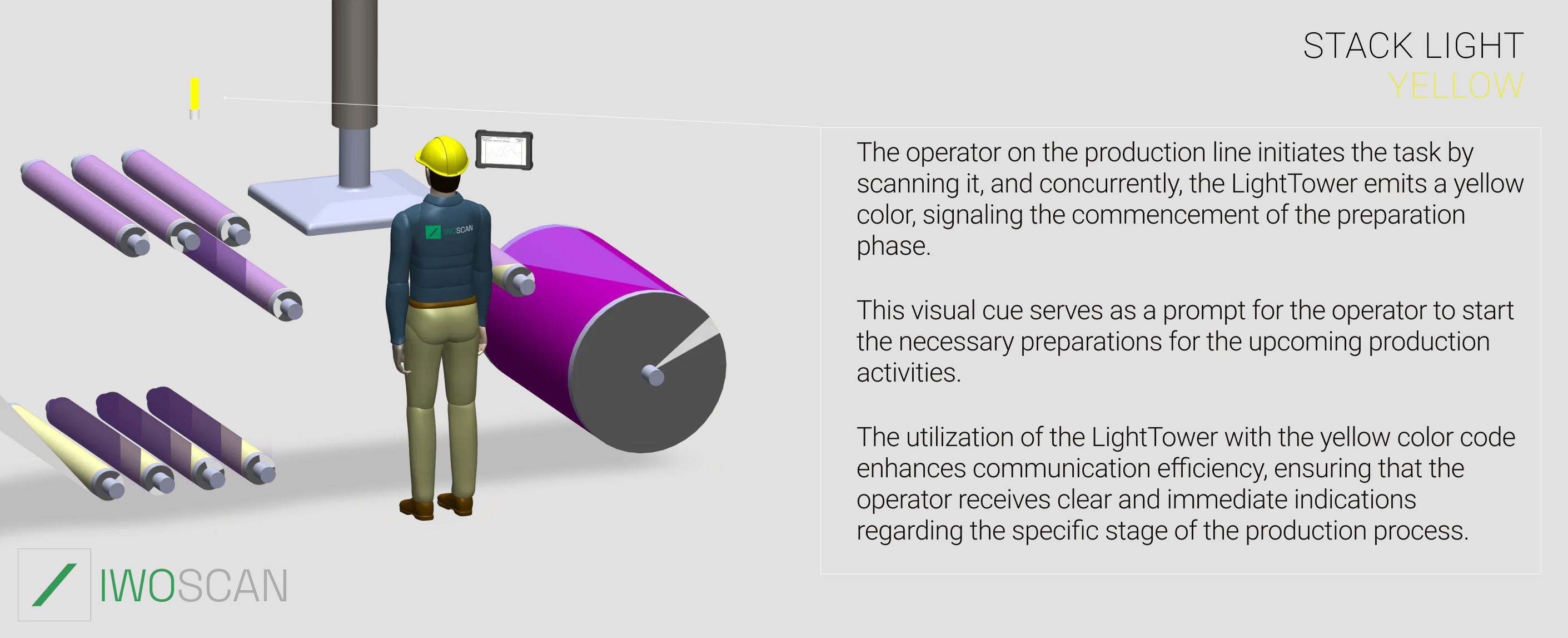

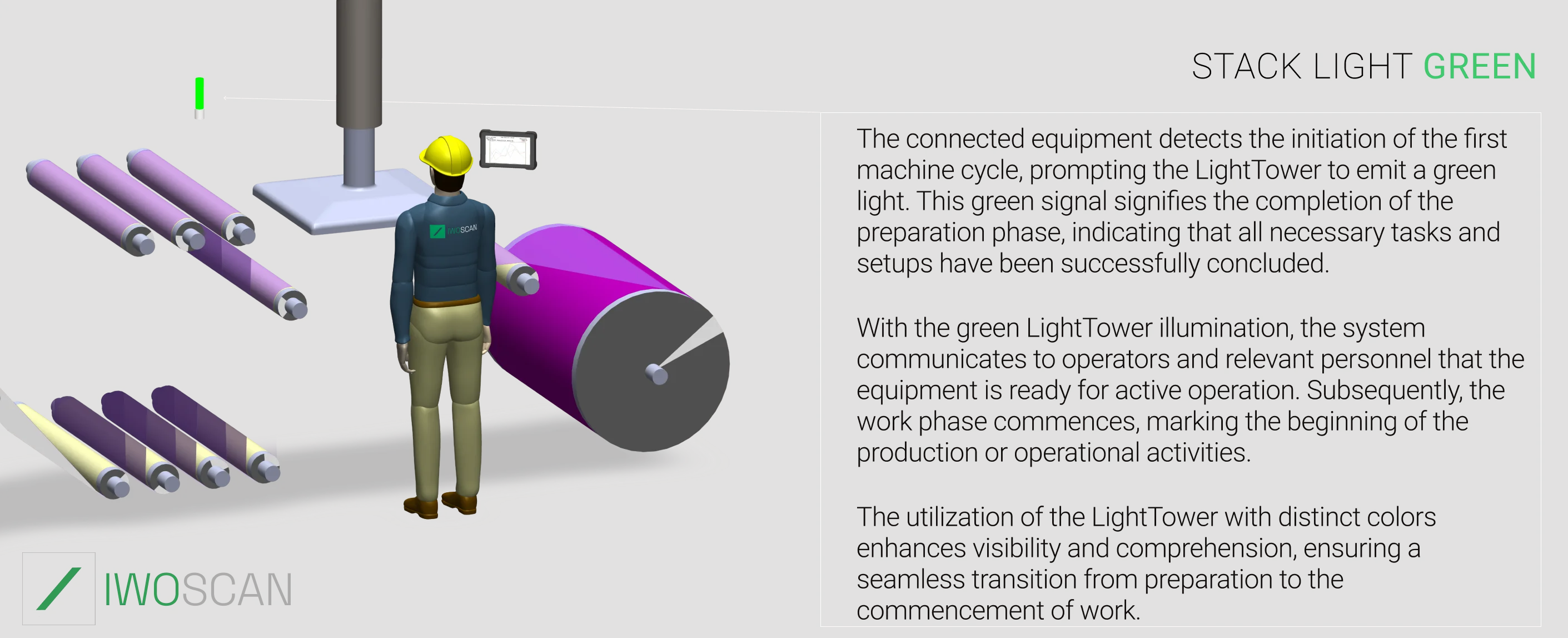

Cloudless Option Iwoscan is an exceptionally flexible tool, typically operating in cloudless mode. However, it can transmit data directly to the client's database without relying on external connections. This option is also applicable to the Basic set. It's essential to note that without the cloud, there won't be an extra backup for data, and the data history will be retained for a maximum of 2 years. Data Storage Alternatives Iwoscan ensures strong data security, safeguarding your information on the device for up to two years for peace of mind and long-term retention. However, data stored in internal memory may be vulnerable to equipment failure. Our cloud-based data backup plan offers unlimited backup, ensuring your data is safely stored for your convenience. Enhanced Workforce Performance Enable seamless communication among your workforce, utilising performance recognition and reward features, and establish continuous feedback loops for ongoing improvement. Workplaces communicate with each other through a local network broadcast system, enhancing connectivity and collaboration. Advanced Event Logging and Timing Features Maximise your efficiency with the integrated text input for event logging, precise timing using clock functionality, and versatile data capture with built-in barcode reading and RFID capabilities, ensuring seamless operations and comprehensive tracking of events. Effortless Wi-Fi Connectivity Achieve smooth Wi-Fi communication and simplified device setup and operation, while interactive dashboards provide precise insights for enhancing operational efficiency, making the most of your connected experience. Self-Reliant Data Processing Our system operates independently, ensuring no reliance on external servers for basic data processing, guaranteeing your data's security and availability. Picture this: after the Iwoscan team installs our hardware into your factory production line, let's dive into a vivid case scenario to showcase the seamless orchestration of operations. Get ready for a firsthand glimpse into the transformative power of Iwoscan in action! Imagine this scenario: the production manager is handed a task to assemble an order, and it's no ordinary task. This challenge involves orchestrating 5 production lines, each with unique production outputs. To add a twist, an international team has joined the mix. The production manager must onboard new team members and craft interactive instructions, impart machinery know-how, amp up team engagement, and ensure the entire process runs smoothly, steering clear of any potential mishaps. It's a dynamic puzzle of people and production, and the production manager is at the helm, ready to tackle it all! In this scenario, the production manager gets an assistant (Iwoscan) to tackle the challenges. You can prepare instructions for your operators simultaneously and scale across your entire assembly line effortlessly, leaving no room for interpretation or assembly mishaps. Iwoscan seamlessly meshes with your manufacturing machinery, ensuring a streamlined workflow. It goes the extra mile by furnishing your new team members with task instructions (available in multiple languages). Moreover, Iwoscan empowers operators to log spoilage or material loss in real-time during shifts, safeguarding against costly collateral damage. It's like having a superhero sidekick for your production team! Meanwhile, Iwoscan takes charge of overseeing everything. The LightTower (available colours: Grey, White, Yellow, Blue, and Red), intricately connected to each machine, provides a panoramic view of activities unfolding across production lines. Picture this: as the production manager meticulously crafts instructions and the production department experiences a lull, the appearance of the grey hue on the stack light signals a crucial message. This distinctive colour serves as a visual indicator, broadcasting to operators and personnel that the production line or machines are intentionally on pause—no operational or manufacturing activities are underway. It creates a clear and easily recognisable visual cue, a deliberate signal of the equipment's status, ensuring everyone is in the loop about the intentional cessation of production. It's like a visual symphony orchestrated by Iwoscan for streamlined communication on the factory floor! Watch the manufacturing process unfold as the production manager fires off instructions and vital information to the team, kickstarting the production flow. Simultaneously, the operator dives into action, igniting the registration process by effortlessly scanning their personal bar-code ID or RFID tag using the built-in reader. Bar codes play a versatile role here, doubling up as task IDs or acting as messengers for the production manager, who can seamlessly dispatch a list of tasks directly to any workspace through the intuitive Iwoscan cloud application. It's a symphony of coordination and efficiency, all set in motion with just a scan! Picture this dynamic scene: the production line task springs to life the moment the operator scans it. Simultaneously, the LightTower bursts into a vibrant yellow glow, signalling the initiation of the preparation phase. This visually appealing signal is a vibrant reminder, encouraging the operator to prepare for upcoming production activities, including setting up the workplace, tuning equipment, and gathering necessary materials. The fusion of the LightTower with this yellow colour code doesn't just add flair—it improves communication efficiency. The shift manager and the rest of the team get clear and immediate indications about the specific stage of the production process, turning every task into a well-coordinated performance on the factory floor! Get ready for a revolution in team communication! Every team member receives personalised instructions and specific information, breaking down language barriers, especially for foreign operators. Iwoscan ensures your new team members are armed with task instructions, schedules, and more. As the initial machine cycle starts, a symphony of interconnected equipment triggers the LightTower to radiate a vibrant green light. Time is ticking, and the meticulous logging of the time interval from task activation to detecting the first cycle becomes the cornerstone of preparation time. When that green signal shines, it's a grand finale—the preparation phase is a wrap, indicating the completion of all essential tasks and setups. The green LightTower serves as the beacon, broadcasting to operators and relevant personnel that the equipment is ready for action. With this radiant cue, the work phase begins, ushering in the commencement of production or operational activities. Using LightTower's unique colours isn't just for display; it's crucial for making processes more efficient. It enhances visibility and understanding, ensuring a seamless transition from the preparation phase to the exciting initiation of work. It's the visual language that speaks volumes on the factory floor!

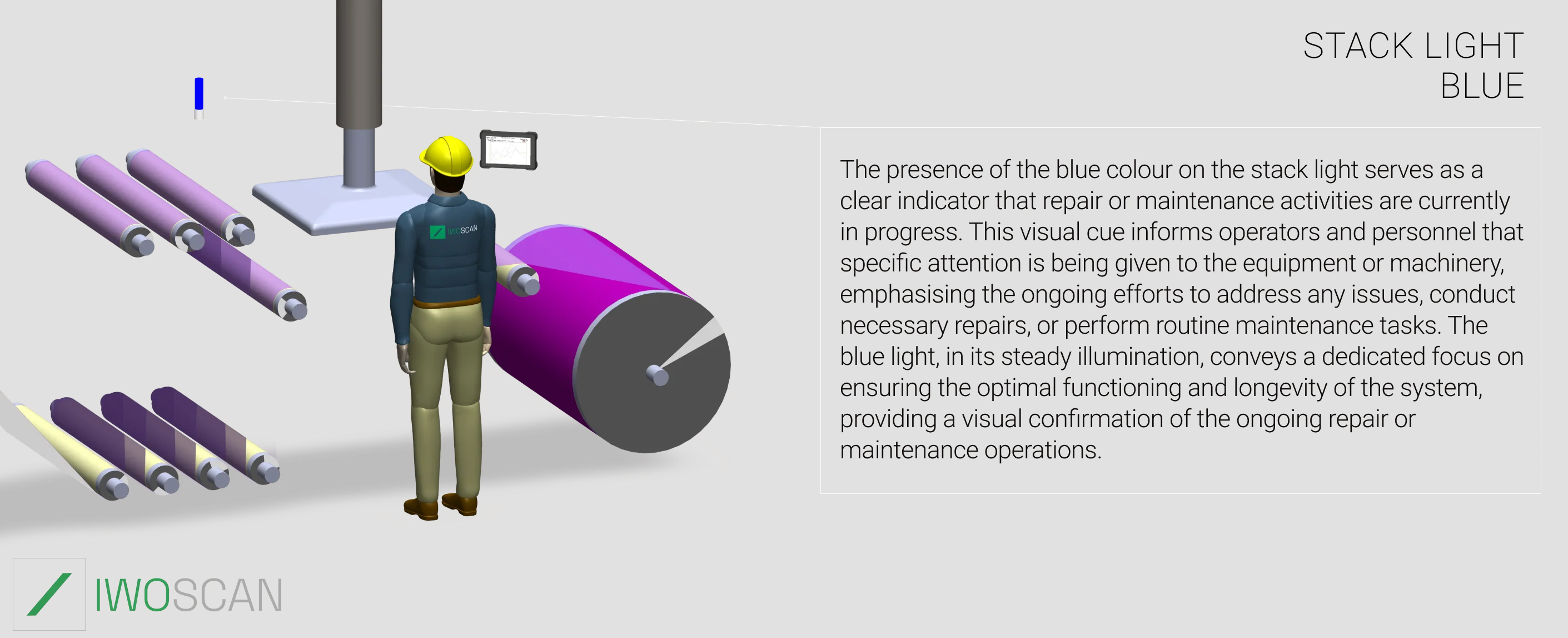

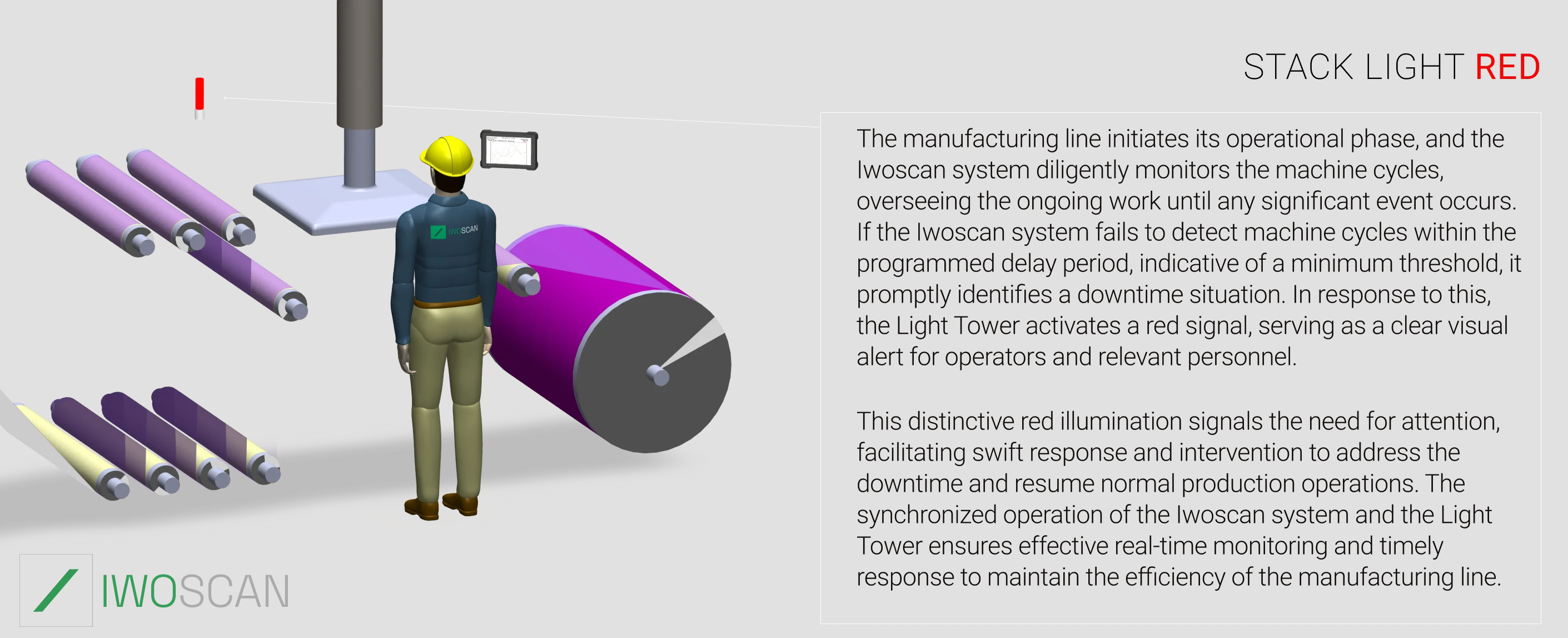

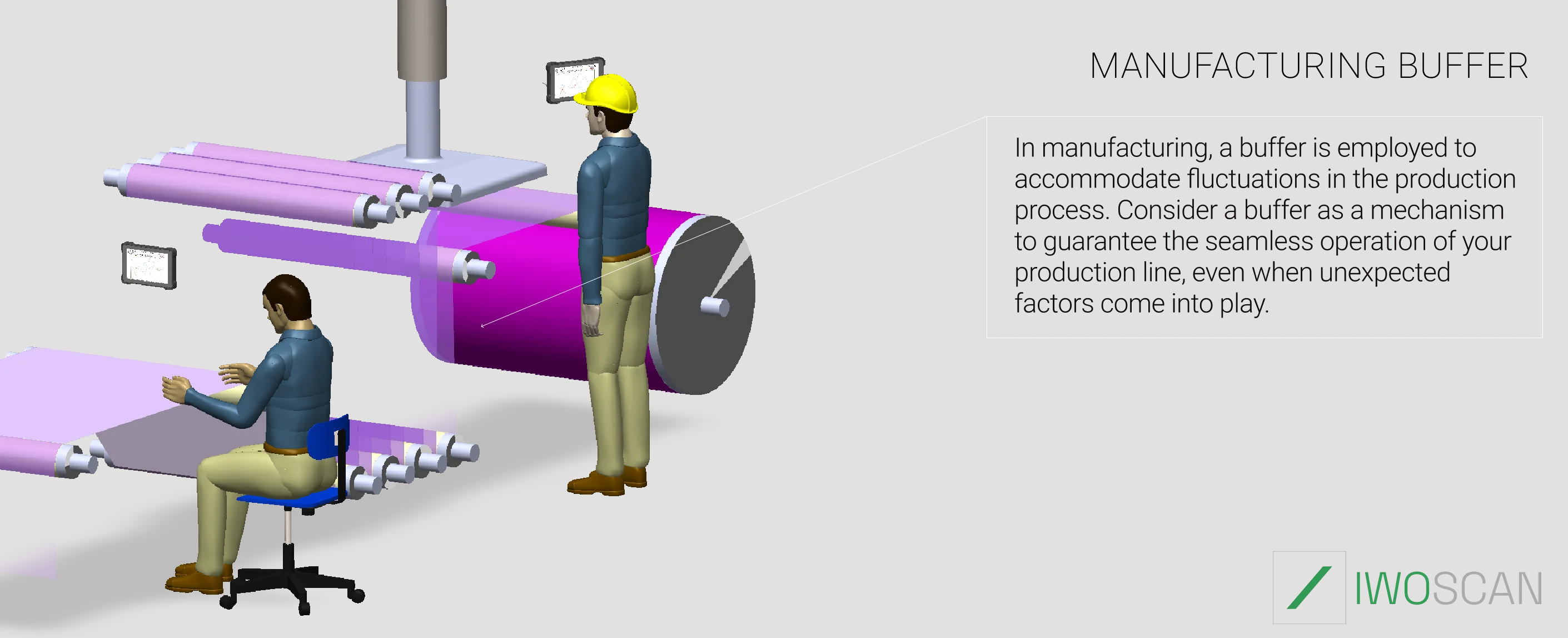

The show begins with that initial signal detection! After wrapping up the current task, the operator seamlessly circles back to dive into the next task if there's more in the queue. It's a continuous flow of action, keeping the momentum alive! Enter the world of Iwoscan's solution, where the production manager becomes the maestro of team dynamics! Boosting team engagement and overall morale is a breeze—whether it's swapping operators during production, granting short breaks, or injecting a bit of friendly competition into the mix. Need a breather? The operator scans the relevant bar code ID and awaits a seamless replacement. If the shift isn't done, but the task is wrapped up, the operator smoothly transitions to another workplace, ready to embark on the next dynamic challenge by scanning the bar-code ID. But that's not all—imagine the production manager sparking healthy competition among operators, fueling a spirited quest for top-notch quality and quantity results. It's not just production; it's a performance, and everyone's a star in the Iwoscan production show! Moreover, the production line faces challenges from attrition or mechanical issues, which can significantly impact operators' morale. In the face of such challenges, Iwoscan steps in to mitigate downtime. However, if there are lingering issues with the machinery, Iwoscan extends an invitation for support. Enter the stack light, pulsating with a vibrant blue hue. This isn't just a light; it's a distinctive signal, a visual beacon calling for external attention. The dynamic play of the flashing blue light communicates various scenarios—whether it's a call for maintenance, a need for materials, or an alert to address specific issues. The energetic rhythm of the flashing blue light skillfully captures the urgency of the situation, compelling operators and relevant personnel to swiftly address the highlighted concern and take necessary actions to ensure the equipment's or production line's seamless functioning. It's not just a signal; it's a call to action! The appearance of the blue on the stack light unmistakably signals the ongoing execution of repair or maintenance activities. This visual indicator communicates to operators and personnel that focused attention is directed towards the equipment or machinery, underscoring the continuing efforts to address issues, carry out essential repairs, or perform routine maintenance tasks. The steady illumination of the blue light emphasises a dedicated focus on ensuring the optimal functioning and longevity of the system, offering a visual confirmation of the ongoing repair or maintenance operations. Still, worst-case scenarios are sometimes inevitable, and downtime comes in the present. The operational phase of the manufacturing line commences, with the Iwoscan system diligently overseeing machine cycles and monitoring ongoing work until a significant event occurs. If the Iwoscan system does not detect machine cycles within the programmed delay period, indicating a minimum threshold, it promptly identifies a downtime situation. In response, the Light Tower activates a red signal, providing a clear visual alert for operators and relevant personnel. The distinct red illumination serves as a signal for immediate attention, enabling a swift response and intervention to address the downtime and resume normal production operations. The coordinated process of the Iwoscan system and the Light Tower ensures effective real-time monitoring and timely response to uphold the efficiency of the manufacturing line. Starting the manufacturing journey comes with difficulties like issues on the production line, problems with management, and the chaos of bringing in new team members. These challenges can be sorted into three main groups. Complications compound as manufacturing lines navigates through distinct stages, introducing inaccuracies and upping the risk of defects. While traditional buffering areas were a go-to for risk mitigation, their efficacy could use a boost, especially with the complexity and elongation of the production process. Enter the tale's hero—implementing a solution like Iwoscan becomes imperative. It's not just about identifying defects mid-process; it's about swiftly disseminating this knowledge across the manufacturing line, empowering operators to tweak their inputs for optimal efficiency. It's a game-changer in the realm of manufacturing solutions!

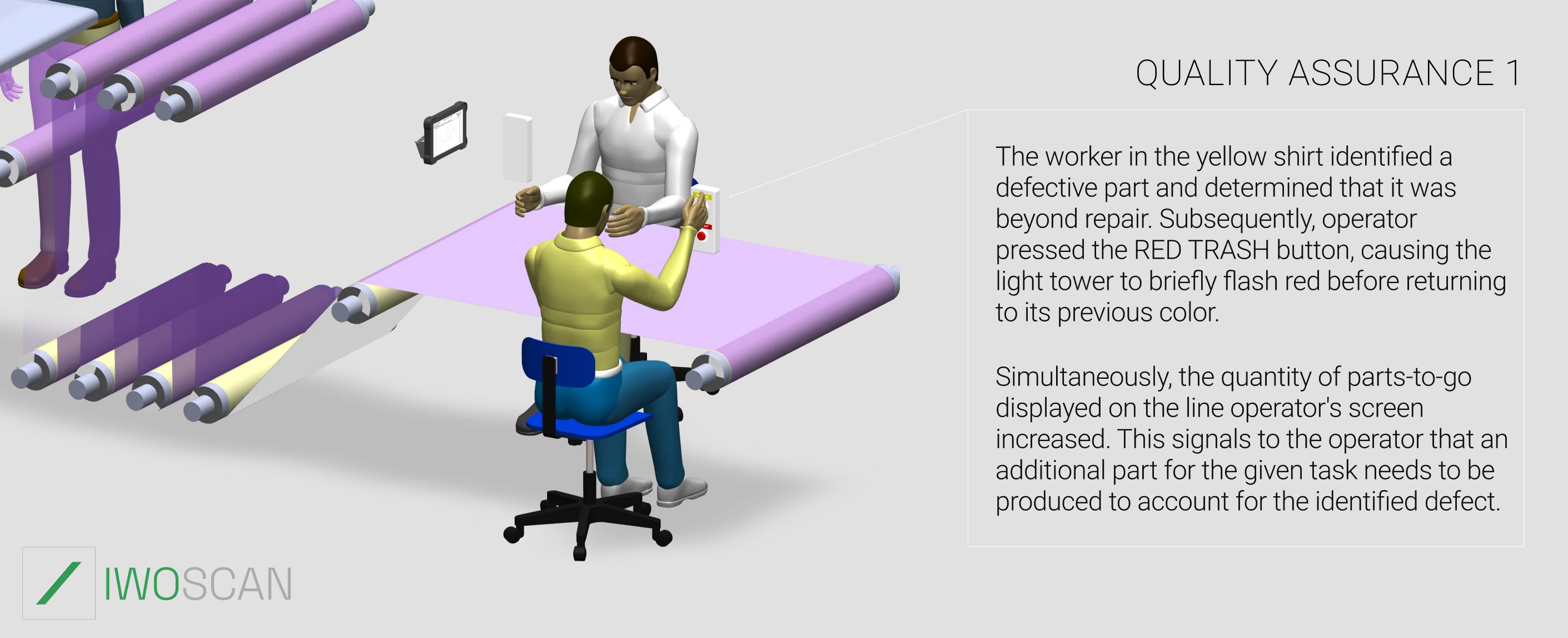

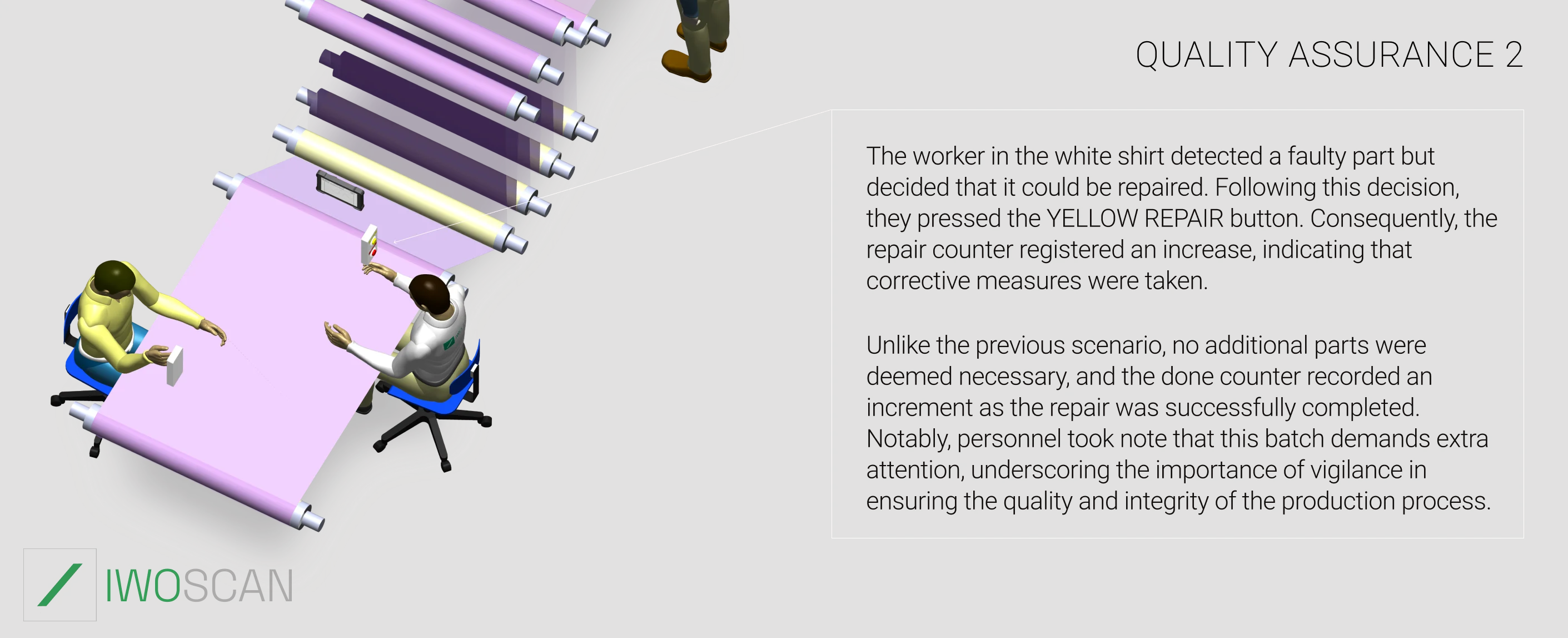

Downtime often brings a host of unexpected challenges into the mix. But fear not! Iwoscan allows operators to seamlessly log spoilage or material loss in real-time during shifts, putting a barricade against potentially costly collateral damage. In practicality, Iwoscan emerges as the linchpin for identifying defects mid-process. This timely identification transforms the gatekeeper or Quality Assurance (QA) operator into a communication maestro, swiftly liaising with their colleague at the inception of the manufacturing line. It's not just a tool; it's a dynamic force in preventing hiccups and ensuring a seamless production journey.

This real-time insight makes proactive adjustments to instructions or material quantities a breeze. Picture this: the QA operator, armed with valuable information, transforms into a decision-making wizard, contemplating the fate of a defective product. Options abound—perhaps it finds new life in other production lines, championing sustainability, or seamlessly integrates into different production stages. It's not just decision-making; it's a strategic vision of possibilities that keeps the production journey dynamic and adaptable! Unlocking the flow of crucial knowledge is critical to achieving manufacturing excellence and amplifying your return on investment (ROI). Dive into the power of our distinctive traceability feature, providing management with profound insights into work processes. Uncover the secrets: know where materials journeyed, who took charge of what, and gauge how seamlessly your process weaves through current conditions. Yet, bear in mind the prowess of Iwoscan extends beyond this scenario, presenting a comprehensive toolkit for elevating your manufacturing performance across the board. It's not just about knowledge; it's about mastering the art of performance! Embark on a journey to witness the transformative impact of Iwoscan on the manufacturing industry. Dive into the specifics by exploring each applicability page to unravel how Iwoscan can revolutionise and bring unparalleled benefits to your organisation across these diverse areass: Overall Equipment Effectiveness (OEE) Quality control in a continuous production line

Need help spotting your niche in the mix? No worries! We've got you covered. Let's create a bespoke solution crafted specifically for your unique demands.

What does the Iwoscan solution entail?

What does the Iwoscan basic set consist of, and what is its appearance like?

What does the premium set encompass, and what is its visual appearance?

Why is a Subscription Plan necessary?

How do you go about installing Iwoscan hardware in your production line?

What are the primary features of Iwoscan?

Real-life scenario involving Iwoscan

Interactive Instructions

Operator-Friendly Environment

Easy Global-Onboarding

Boosted Team Engagement

Managing Downtime

Downtime Outcome

Real-Time Spoilage Preventation

In which contexts can Iwoscan be applied?

Published on 15.12.2023

Let's dive right into how Iwoscan can reshape your manufacturing pipeline

Let's dive right into how Iwoscan can reshape your manufacturing pipeline

Comments

No comments yet!Add a Comment

You must be logged in to post a comment.